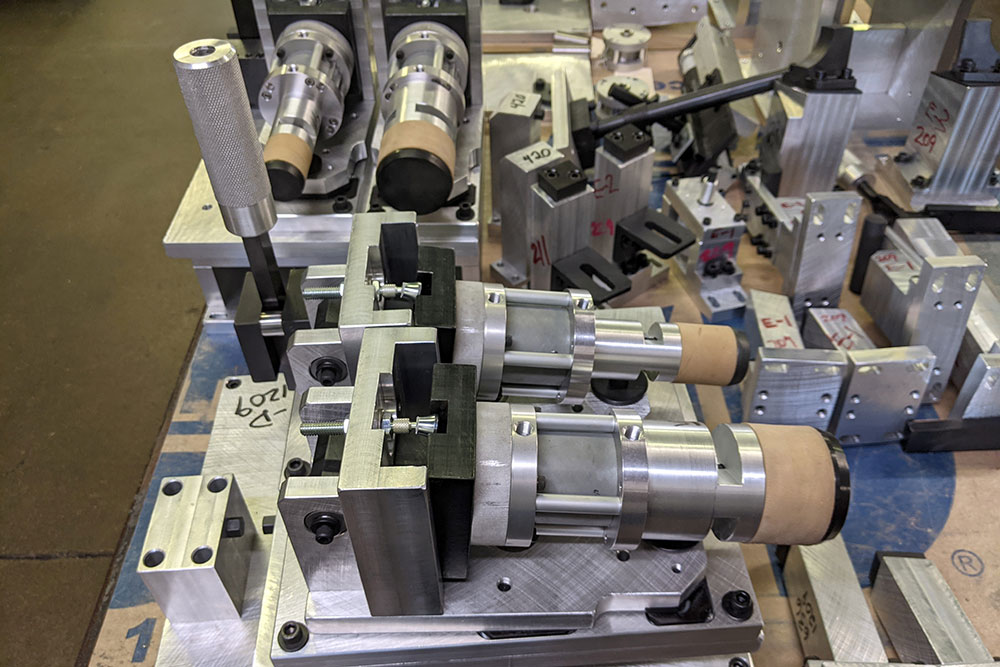

Machining & Fabrication

We have extensive machining capabilities to support your prototype or small volume production needs. We have various equipment available for contract machining. This includes CNC mills and lathes, plus various forms of grinding (surface grinding, Blanchard grinding, jig grinding, ID grinding, and OD grinding). In addition to the more standard machining capabilities, we also offer 7-axis Swiss lathe machining with up to 20 mm diameter.

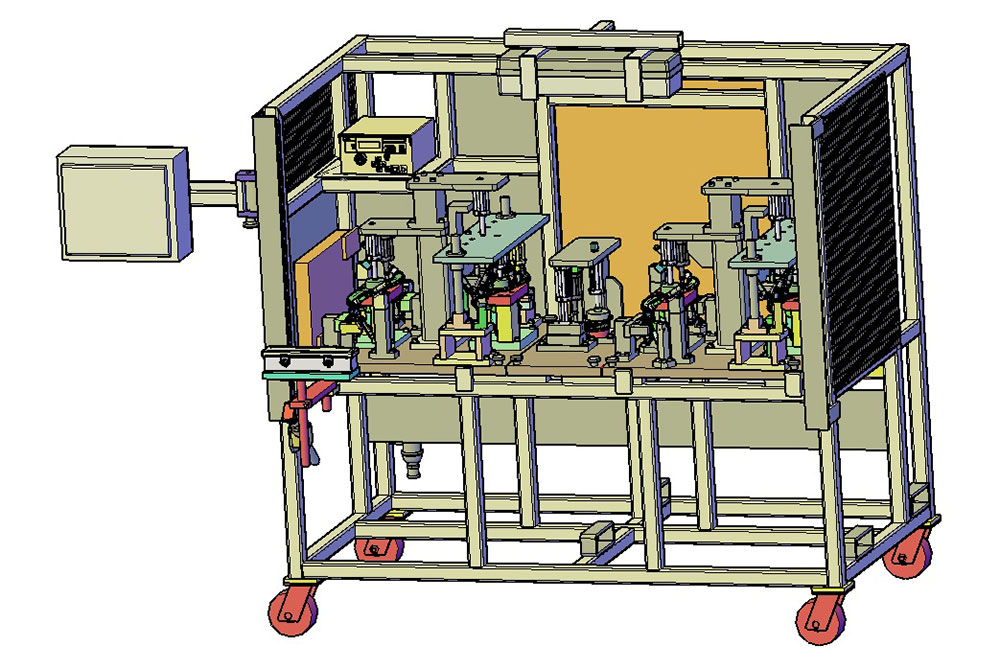

Design

We use SOLIDWORKS as our primary CAD software, but also have AutoCAD capabilities, along with decades worth of design and modeling experience. As part of our offering, we review our customers’ needs and requirements and translate them into a product design, along with manufacturing drawings. Most of what we produce is custom-designed in house. We can confidently state that we can also help you with your design needs.

CMM Measurements

Our Zeiss CMM with an impressive 108” x 46” x 34” measurement volume is covered by our ISO/IEC 17025-2017 accreditation. No matter if you are just looking to verify the dimensional accuracy of your parts, an additional quality inspection, or a formal 3rd party certification, we can help.

3D Printing

Our 3D printer is available to print customer-designed parts. We can print various materials: ABS, ASA, Nylon, including glass fiber reinforced and carbon fiber reinforced, PETG/PET, PLA, Polycarbonate, and TPU/TPE. It does not matter if you need functional prototypes, end-use products, fixtures, jigs or tooling for your manufacturing process, or set-up parts, we can help. A 14” x 14” x 12.5” print volume should cover most, if not all, your 3D printing needs.

Reverse Engineering

As a machine builder with extensive experience in manufacturing process and tooling design and build, we understand how to solve problems and how to design various items from scratch based on functional requirements, including all the required tolerances and materials. If you have an item or device you need built, but no drawings, we can help with recreating those.

Equipment Upgrades

We not only design and build new equipment, but we can also help with refurbishing and upgrading existing equipment. No matter if you have an old, worn-out piece of equipment that needs to be brought back into an as-new condition, or if you are looking at installing safety upgrades or error-proofing, or want to add a new product configuration or automation, we would be happy to discuss your goals and a solution with you.

Ken-Bar is a vertically integrated machine builder and system integrator. Our in-house design and manufacturing teams are supported by a precise measurement lab accredited to ISO/IEC 17025:2017.

To solve complex manufacturing issues, you need experienced problem-solving solution providers. Ken-Bar is ready to talk about your project.

ISO/IEC 17025:2017 Accredited

FANUC ASI

Association for Advanced Automation